Counterpoint: Why Cadmium QDs won't Die

It has been said that a good lawyer must be able to argue both sides of a case to be effective. While I don’t have a law degree, I will take the stand here (on my soapbox) and apply this principle to the matter of cadmium in QD display technology.

You may have read my most recent article Cadmium QDs are on the Chopping Block, which summarized the status of RoHS regulations for heavy metals in displays (Cd and Pb are the important ones). Here I provide a counterargument as I take the position that the future of Cd-containing QDs in displays is not over yet.

Nanosys has promoted their Hyperion film which leverages a Cd-containing green QD and InP red to achieve excellent gamut/brightness but still meets RoHS specifications (<100 ppm Cd). This is a shining example of the creative games chemists can play with different material types, which makes one think about what other options are out there.

Vizio P-series quantum uses the Hyperion film for example. Even if the RoHS regulations return to 100 ppm Cd, there will be no need to adjust their technology.

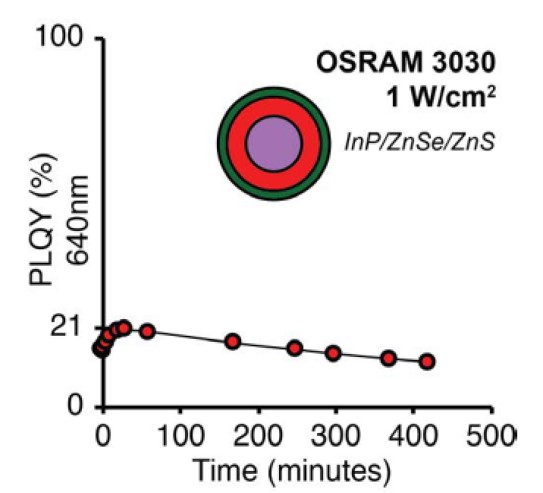

So far, the only type of QD material to demonstrate the reliability necessary for on-chip operation is red CdSe QD (Osram/PLT). There have yet to be any demonstrations of green QDs with on-chip QD reliability, although OSRAM claims they are working on this. Also, the US Dept. of Energy has funded multiple projects focused on improving the performance of non-Cd QDs for on-chip environments, but the early data suggests they are still a long way from commercial status. Here you can see some results of InP-based red QDs with performance that leaves a lot to be desired. If I had data for CdSe from 2015 I bet it would have looked similar.

These currently available on-chip products are not yet being used for display technology, only lighting. And in that application a narrow green emitter is not that useful. But red can be a game-changer when it comes to efficacy, which is why red has been the focus. This continues to be the case for non-Cd approaches, with red being the preferred starting point.

One of the reasons CdSe QDs are so much better then the rest is that they have been studied so much longer. While synthetic approaches for both InP and CdSe were developed in the ’90s, CdSe research took off due to the relatively simple synthetic procedures for growing shells and producing high quantum yields with readily available chemicals and colloidal chemistry techniques. All one needed was a basic chemistry lab and cheap skilled labor (grad students). Focused effort on improving the performance of InP however did not occur until the mid to late 2000s. Of note is the broadness of InP compared to CdSe. It has taken countless research hours by the likes of Nanosys, Samsung, and a number of academics to reach peak widths in the 35-40 nm range for InP. I suspect this was achieved decades ago for CdSe, which can easily be produced with <25 nm peak width these days.

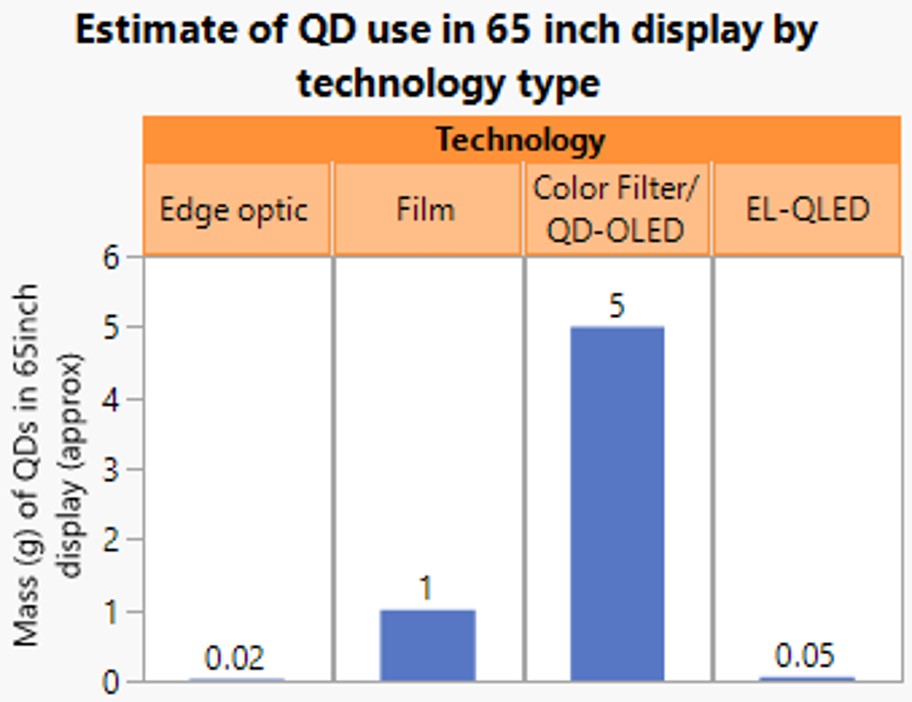

The way RoHS defines their restrictions is by a simple wt% (ppm) specification in a single component (QD film for example). This does not consider the total amount of material used in a particular application. Ultimately, if the goal is to reduce the total amount of hazardous material used, then one may want to consider how much is used in the entire display, not just in a particular component. As a thought exercise I have estimated the amount of QDs used in four different technologies that have been or are proposed for QD-displays. The exact amounts would vary depending on the type of QD, but my goal here is to give you a feel for the vast differences in the level of QDs required for these technologies.

As you can see, the QD-OLED or color filter approach uses way more QDs than any of the others. And the now defunct edge-optic and the EL-QLEDs of the future use vanishingly small amounts of QDs. In EL-QLED this is because the QDs make up an ultra-thin layer (10s of nm) of the device. Clearly, it would make a lot of sense to allow this type of approach from a regulatory perspective if the specs are anything like what we hope they will be (improved efficiency, viewing angle, brightness, thin, etc).

Another interesting observation from the graphic is the current trajectory that QD usage is following – It’s exponential. That is until you get to EL-QLED. It makes one wonder about the various forces at play here. QD suppliers may not like the idea of displacing a cash-cow technology with one that would sell fewer QDs. And panel makers don’t like adding cost.

One more point. The estimates I provide here are for the mass of the entire QD, which are of course not made of pure Cd. Even when they are CdSe core QDs, the shells often do not contain Cd, meaning the QDs can be <<50% Cd by weight.

So perhaps Cd can breathe a sigh of relief.

It seems there are still many advantages to using this extraordinary element, and a number of situations where it will happily find a home in displays for many years to come. I will now step down from my soapbox and let the real lawyers argue about the future of cadmium.

Thanks for reading!

This article originally appeared on DailyDisplay